The pure, safe, high-tech, sustainable approach to food, beverage and pharmaceutical plant lubrication

BY JIM GIRARD, VP AND CMO, LUBRIPLATE LUBRICANTS CO.

Food grade lubricants have been a part of industrial lubrication since the early 1960s. They were first introduced and used in the United States market. Since their initial development, there have been great high technological advancements with research, development, introduction and use of food grade lubricants.

First, let’s review the evolution of the development, approval and monitoring process of food grade lubricants.

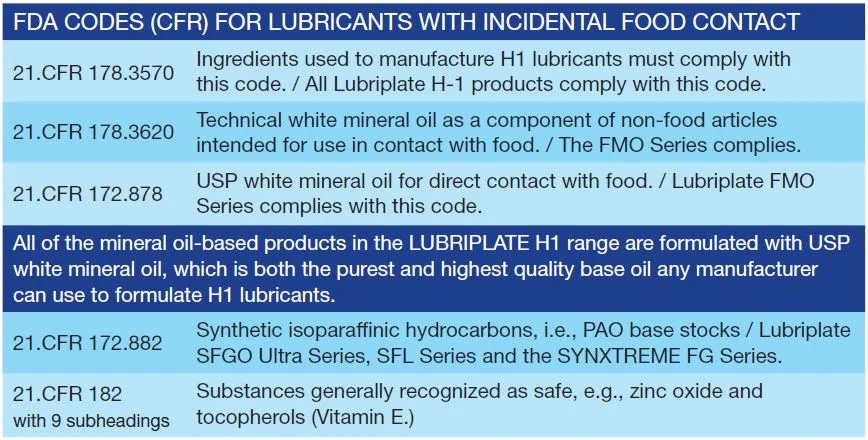

The Food and Drug Administration (FDA) of the United States of America produces its Code of Federal Regulations (CFR). Title 21 of the FDA’s CFR presents many sections that authorize ingredients which may be used to produce food grade lubricants. The chart below displays the sections in the FDA’s Title 21 and presents brief descriptions of some of the more popular ingredients used by lubricant manufacturers to produce food grade lubricants.

In the early 1960s, the Food Safety and Inspection Service (FSIS) of the the United States Department of Agriculture (USDA) committed to monitoring and authorizing lubricants that could be used to lubricate machinery which had incidental contact with the food. This became known as the USDA/ FSIS “Prior Approval Program for Non-food Compounds and Proprietary Substances.” The FSIS published its “White Book,” which listed lubricants that had been authorized as USDA H1 (lubricants authorized for use in federally inspected meat and poultry plants for incidental contact with the food product). The FSIS’s authorization process and program was based on the FDA’s Title 21 list of approved ingredients. This program for authorization of food grade lubricants quickly spread and was recognized by food, beverage and pharmaceutical processors throughout the world.

But, this lubricants industry authorization and monitoring program changed drastically in 1998 when the USDA/FSIS eliminated its “Prior Approval Program” and “White Book authorization program for non-food compounds. Was the lubricants industry to engage in self-monitoring for H1/food grade lubricants, or would a third-party professional monitoring organization step forward and adopt a food grade lubricants monitoring program?

The National Sanitation Foundation (NSF), based in Ann Arbor, Mich., stepped forward and produced an industry authorization and monitoring program that closely mirrored the former USDA/FSIS program. The worldwide lubricants industry quickly committed to the NSF’s program, and today, the NSF is the leader is authorizing and monitoring H1/food grade lubricants for all lubricants manufacturers. NSF H1 authorized food grade lubricants are posted on the NSF’s website.

The International Standard Organization (ISO) also developed the ISO-21469 certification and registration process for lubricants used in specialized industries such as food, pharmaceuticals, cosmetics and animal feed manufacturing. This is a very stringent standard and registration process in which lubricants manufacturers must first be registered and maintain the ISO-9001 Quality Management standard that demonstrates the commitment to an overall Quality Management System.

Finally, H1/food grade lubricants also are part of Hazard Analysis Critical Control Point Programs (HACCP). In the United States, the FDA and the USDA demand that food and beverage processors develop HACCP programs in which lubricants may be considered as potential chemical hazards. However, if food and beverage processors switch to 100 percent H1/food grade lubrication programs, then lubricants are not considered potential chemical hazards and a HAACP plan is not necessary for a 100 percent H1/food grade lubrication program.

Lubrication suppliers should be aware of all industry standards affecting H1/food grade lubricants. Food grade lubricants packaging and literature should clearly define the product and relate to all of these industry standards. Consumers must watch for unscrupulous and confusing claims on packaging and in product literature.

Advances in technology

H1/food grade lubricants have not been immune to high technology. In the 1960s there were not many fluid base stocks, additives or grease thickeners available that were listed in the FDA’s Title 21 CFR sections. This resulted in poor performance of H1/food grade lubricants.

However, technological advancements have changed the availability of H1/food grade lubricants. In 2015, H1/food grade lubricants can accommodate every application on machinery in food, beverage and pharmaceutical processing facilities, from refrigeration compressors, to freezer conveyor chains, to gear boxes to filling, seaming and closing equipment.

For example, in the early 1960s, it was impossible to find an H1/food grade grease that delivered both anti-wear and extreme pressure protection. Today, calcium sulphonate-thickened greases made with USP white mineral oils and synthetic polyalphaolefin (PAO) base stocks are truly anti-wear and extreme pressure lubricants.

Lubricant manufacturers have been able to add antimicrobial additive to their products. Anti-microbial additives help to prevent the decomposition of lubricants caused by microorganisms. Many anti-microbial additives are registered with the EPA.

The use of synthetic polyalkylene glycol (PAG) base stocks to manufacture H1/food grade gear oils has produced H1/food grade gears oils which deliver extended drain intervals and unmatched anti-wear and extreme pressure protection. Gear reducer original equipment manufacturers (OEMs) now have no fear in recommending H1/food grade synthetic PAG-based gear oils.

Synthetic polyolester (POE) food grade fluid technology now delivers optimum lubrication protection for high heat oven chains in bakeries. POEs have unmatched oxidation stability that virtually eliminates carbon deposits and keeps the chains clean.

Silicones and PTFE are also used very effectively as H1/food grade lubricants.

Synthetic H1/food grade technology also helps to consolidate the amount of lubricants required. For example, synthetic PAOs work effectively in both air compressors and hydraulic systems. It is possible to use the same ISO-46 fluid for both air compressors and hydraulic systems.

All of these technological advancements in H1/food grade lubricants mean that food, beverage and pharmaceutical processors should not hesitate to convert to a 100 percent H1/food grade lubrication program. Converting to a 100 percent H1/food grade program delivers money-saving lubricants consolidation, a reduction in lubricants misapplication, sustainability and helps to ensure a safe product for the ultimate consumer.

Jim Girard is vice president and chief marketing officer for LUBRIPLATE Lubricants Company, Newark, N.J. and Toledo, Ohio, an ISO 21469 certified lubricants manufacturing company. Visit www.lubriplate.com to learn more.